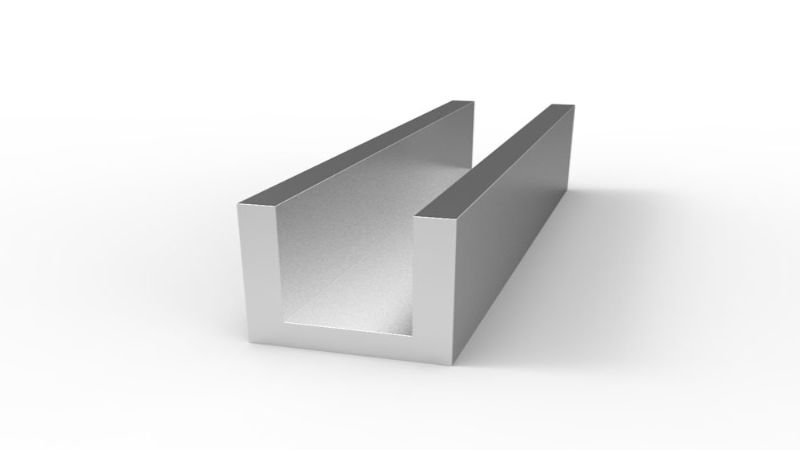

As opposed to aluminum sheet, which refers to any sheet metal aluminum heavier than foil but no thicker than six millimeters, plate is aluminum sheet metal stock thicker than six millimeters. It comes in various forms, including perforated, expanded, diamond plate and painted for use in aircraft and aerospace, beverages and more.

The Type 200 Tooling Plate

The term Type 200 Tooling Plate was created by Alcoa in reference to an improved tolerance for 6061 T651 rolled plate. This was to bring a superior product to market with higher quality than the standards permitted in the Aluminum Association Standards and Data Book.

Confusion between Wrought Tooling and Jig Plate and Cast Tool

The term Type 200 Tooling Plate has led to mistaken orders because the term “tooling plate” is often taken to mean cast tooling plate. While cast tooling plate, jig plate, cast tool and CT&J all refer to cast aluminum, the product is significantly different from wrought aluminum plate, such as 6061 T651.

The Key Differences

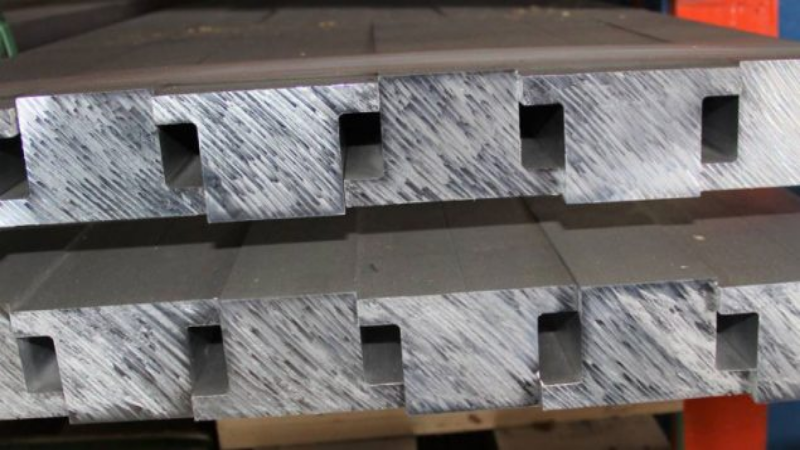

6061 T651 is rolled and heat-treated, which imbues it with physical properties due to elongated grain and the effects of heat. Jig plate and cast tool only undergo homogenization for grain uniformity. 6061 T651 retains higher residual stress from processing but demonstrates higher strength. Jig plate and cast tool have both lower strength and lower residual stress, rendering a more dimensionally-stable product.

Additional Plate Types

Wrought aluminum plate, such as 7050, 7075 and 2024, also comes in additional thicknesses, alloys, tempers and sizes and custom sizes for non-standard requirements in various machining applications.