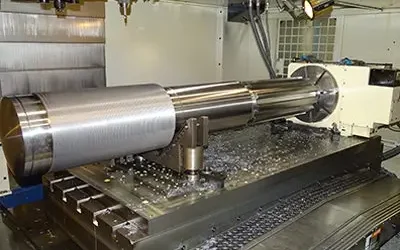

Aerospace components manufacturers are experts in the area of CNC machining for aerospace development. The level of machining, along with the quality of metals used, often determines what can machined. The most experienced manufacturers can, virtually, produce anything the industry requires.

Considerations for Choosing the Right CNC Milling Company

Companies should always seek the most experienced and reliable companies to perform aerospace machining. Top-of-the-line machinery is critical, along with the ability to use it for the desired results. This especially holds true where critical design demands high quality work. Other services may be offered by the shop, which include coating, hardening, or other treatments that may apply after parts have been machined. Usually, companies fare better when they partner with companies that offer full milling services. Companies that can offer quick turnaround times are also ideal to partner with.

Aerospace components manufacturers must approach building specialty molds, grinding down parts, and designing with a mindset that every phase will be 100% accurate. Only top companies can even attempt to approach the manufacturing aspect from this point of view.

Skill and Workmanship Abilities

Another element to look for from manufacturers that provide aerospace is how much a company pays attention to the skill and workmanship of its employees. The best companies will continually reinvest in equipment and state-of-the-art software so as to provide the best services and products possible. Services should also include an ability to integrate every aspect of the manufacturing process, which includes entering an order, to scheduling and monitoring the process in real time.

ISO 13485 and ISO 9001:2008 Certifications

These are critical certifications to possess with regard to any industry that an engineering firm serves. CNC aerospace milling may include solutions for airframe systems, housings, gear boxes, flight control systems, AR component systems, handrails, and more.

Finally, a company’s reputation matters. What does the industry, as a whole, say about the company? Does the company have an impressive list of clients? Can the company manufacture for both small and large orders? How well does the company resolve manufacturing issues? Like anything in life, the best outcomes are often the direct result of partnering with the best.