Aluminum is a very versatile metal and is used in a wide variety of construction, fabrication and manufacturing applications. It is also commonly used by do-it-yourselfers and retail outlets to create a low cost, durable and attractive option for all types of storage and display options.

Best Option

Aluminum T track is one of the most commonly used components for these types of applications. You will find it used on trailers, boats, in kitchens as well as in retail outlets all over the world. This is durable, scratch and wear resistant, and will virtually never show any signs of rust or corrosion, even when used in humid conditions or when exposed to water.

The additional benefits of aluminum T Track are that it is very light and has an extremely high strength to weight ratio. This means that even for use in hanging or holding heavy items it will stand up to the test without adding any substantial weight of its own.

For those retail outlets or manufacturing companies looking for a green option, aluminum offers the better alternative. It can be recycled over and over again, resulting in virtually zero addition to any waste material in landfills when recycled.

The Ease Factor

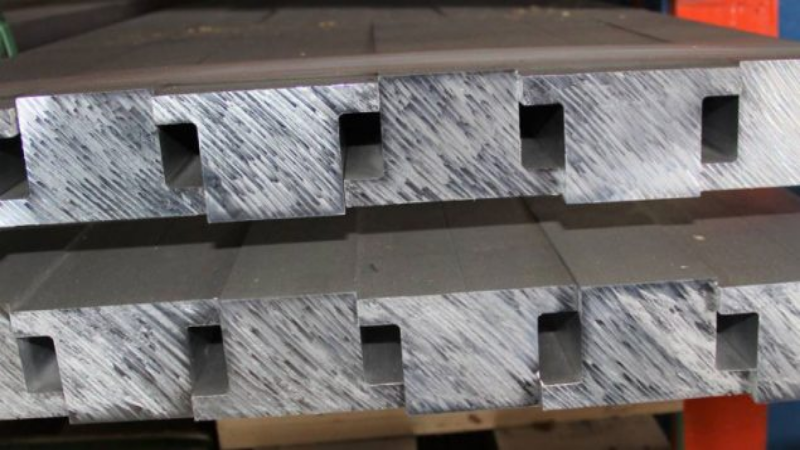

Standard aluminum T Track is sometimes called universal t-track and it can be combined with any other type of component designed for t-track. This means you can mix and match manufacturers without compromising how components will fit together.

This is a positive as it allows fabricators, manufacturers and do-it-yourselfers to shop around for the lowest prices without having to be concerned about components working with the system.

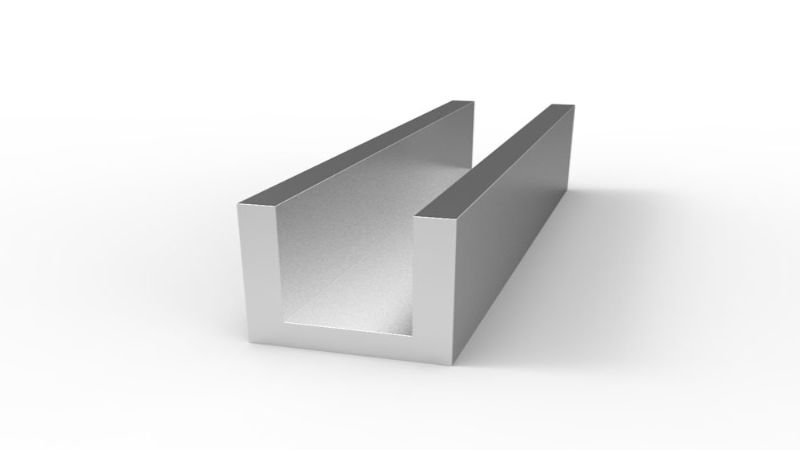

T-track can come pre-finished in any desired color, or it can be left as natural aluminum for a stylish look. It has the groove which resembles the top of the capital T in the track, providing the option to slide bolts into the track and then attach items to the bolts for easy storage or fabrication.

Additionally, most of the aluminum T Track on the market is also pre-drilled along the back of the channel. These holes are typically drilled every 4 inches, ensuring that standard distances between studs or roof rafters can be easily accommodated by the track.

The bolts, which can be either T-bolts or standard hex bolts, simply slide in the T slot on the track. They can be used to create jigs or to attach to the other components of the design.