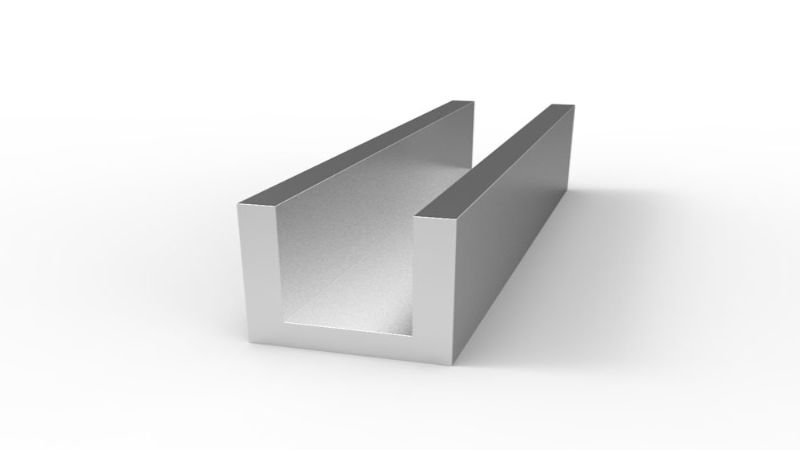

Saving time and processing steps in any type of fabrication or manufacturing process is always going to provide advantages. For industries using aluminum blocks, working with a supplier to provide near net shape components has its benefits that include both price and efficiency.

When your business requires aluminum blocks – near net shape, there are only so many aluminum manufacturers with the ability to provide the quality of aluminum in the shape required to your specifications. Researching online and then comparing your options will be essential to find the best products and the best prices. Look for cast aluminum suppliers offering near net shape production to narrow down your search results.

Cut Processing Costs

By choosing a supplier offering aluminum blocks – near net shape your business will save money on orders long term. There are several different reasons why price savings will come into play.

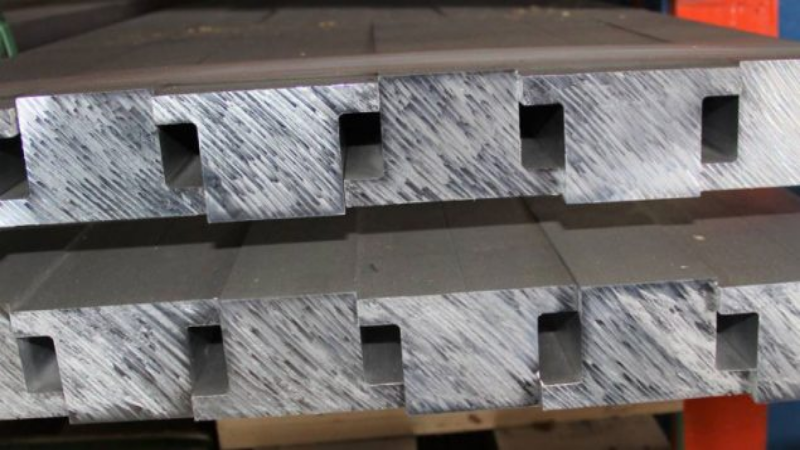

One of the biggest cost saving features will be the limited about of machining services that will be required compared to buying a standard aluminum block. Without having to run each block through additional machining to create the specific shape, the cost of production is decreased.

However, even if some additional machining is required, it is still significantly less than would be expected with the standard aluminum block. Less machining translates to lower costs.

Less Waste

For shipping purposes, choosing aluminum blocks – near net shape also offers a cost saving benefit. As the total weight of the blocks is reduced because you are not paying for the waste material that will be removed from the block in future machining, the price of shipping and delivery can be reduced.

Of course, there will also be a reducing in the need to remove chips and waste from the machining operations if these are done in-house. This too can be a cost saving feature to consider. There is also an associated reduction in the energy required to produce a specific part or component. This may be difficult to quantify for all applications but with fewer processing steps and lower waste in the process there is a net increase in energy efficiency over traditional machining of solid aluminum blocks.

With quality producers of net shape aluminum components, it is also possible to develop a technique that creates a quality surface finish on the parts or components produced. This reduces the need for grinding and surfacing while still maintaining tight tolerances during the process.