A number of different industries can benefit from the wide range of extruded aluminum shapes available for use in particular applications. The mining and construction industries are just a couple examples of those in which the shapes are utilized. A provider of precision metals can supply the aluminum you need for specific applications that require aluminum extruded shapes and precision parts to meet project specifications.

Industrial Applications

Additional industries that can benefit from the shapes include electronics, automobile, and military. The auto industry uses aluminum shapes in their vehicles extensively. Aluminum, as an efficient conductor of heat, is used within the heating and cooling systems of vehicles, and specifically in vehicle radiators.

Extruded aluminum shapes may also be used for other applications in vehicles including engine blocks and chassis. In addition, the shapes may be used in the cooling and heating systems of electronics and computers.

Process of Extrusion

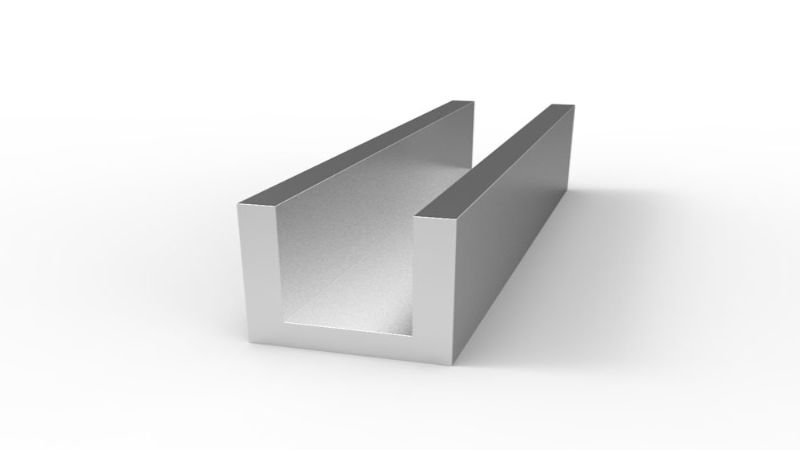

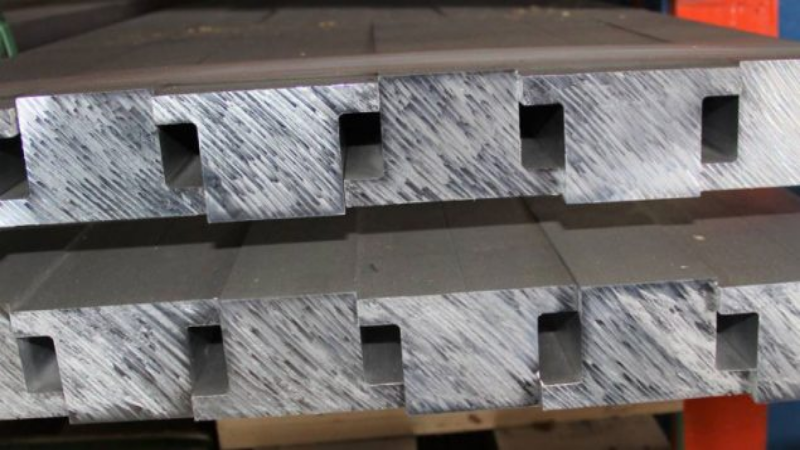

A number of components can be developed through the extrusion process by means of the transformation of aluminum alloy. As aluminum alloy is heated and softened, it is forced through a hydraulic ram or press and subsequently through steel dies that form the desired shape. The aluminum shapes resulting from the extruded process are developed as the billet travels through the die.

Aluminum Extrusions Benefits

In order to inhibit corrosion, no special treatment of the metals is required. Also, due to the aluminum oxide bonded to its surface, which develops protection against outside elements, aluminum possesses natural resistance to wear and tear.

When buildings move or sway, aluminum is able to resist these forces due to its flexibility. As well, the material can absorb impacts efficiently and also retain its strength at the same time. Aluminum is also beneficial as a nonmagnetic material and therefore safe to use around sensory magnetic devices and magnetic fields.

A reliable and experienced aluminum distributor is able to provide extruded aluminum shapes according to your project specifications. As well, a company that offers precision sawing can help make sure that your aluminum shapes and parts are developed and implemented in your project or processes with the required precision.