A diesel flow meter is essentially used during the process of measuring the quantity of fluid. This is done when the liquid is moved at the time of transferring. The meters come with a visual display that can be either mechanical or digital so that the reader can have a look at the measurement easily. Flow meters are used for different types of fluid transfer applications. A diesel flow meter is mostly used for the measurement of diesel.

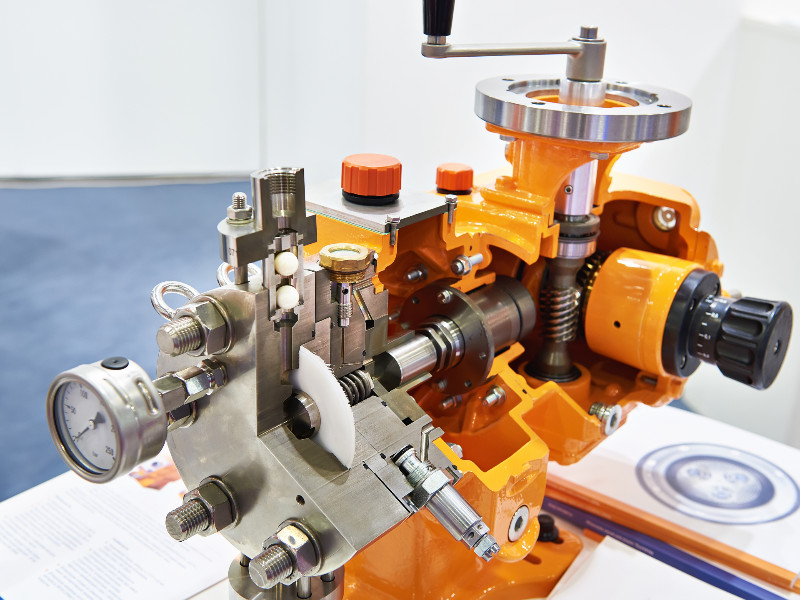

The diesel flow meter has a nutating disk that is crucial for the measurement of the liquid. The fluid enters through the inlet so that it immediately comes in contact with the disk. There is a vertical axis that the disc is positioned along. This is helpful in understanding how much liquid has gone through the meter. There is one diesel flow meter that comes with a minimum of two gears rotating at right angles to one another. This has a T shape and it prevents the liquid from passing through the middle. Magnets present in the rotating gears play a vital role in measuring the liquid. Due to the magnets, a signal is transmitted to the electric reed switch which in turn measures the flow of the liquid.

When one is dealing with a diesel refuelling system, the diesel flow meter essentially measures the amount of fuel that gets transferred in one transaction. This enables the user to know how much diesel has been dispensed into the vehicle. Sometimes, the speed at which the diesel has been transferred is also displayed. Diesel flow meters have a mechanical style tick on the digital display that is mostly powered by batteries. The meters operate on a very precise accuracy level and thus are used in gas stations.