Various industries can receive considerable benefits from the wide array of extruded aluminum shapes available for use in various industrial applications. The construction and mining industries are prime examples of how aluminum is used effectively. The company provides precision metals can supply the aluminum you need for your project, including extruded shapes made from aluminum and precision parts.

Applications for Various Industries

Other industries that can make use of aluminum shapes their extruded include auto, electronics, and the military. The automobile industry utilizes the shapes in vehicles constantly. Aluminum is also an effective heat conductor and is used in the cooling and heating systems of motor vehicles, particularly in vehicle radiators.

Other applications can also benefit from extruded aluminum shapes, including chassis and engine blocks. Also, the shapes can be very beneficial in the heating and cooling systems of computers and electronic equipment.

Extrusion Process

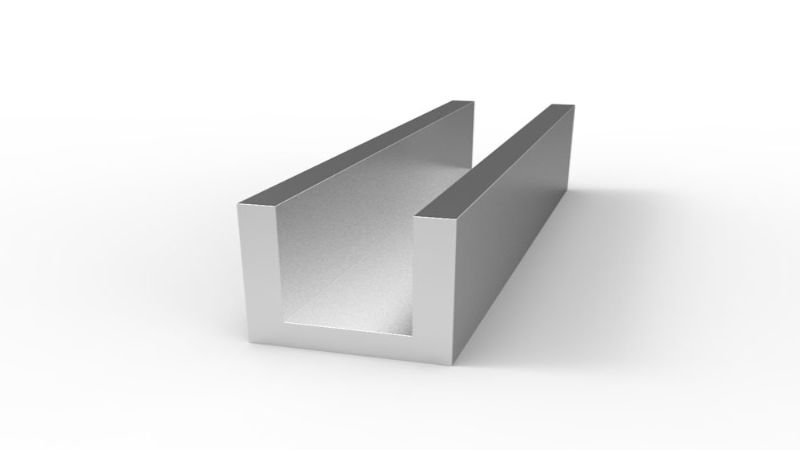

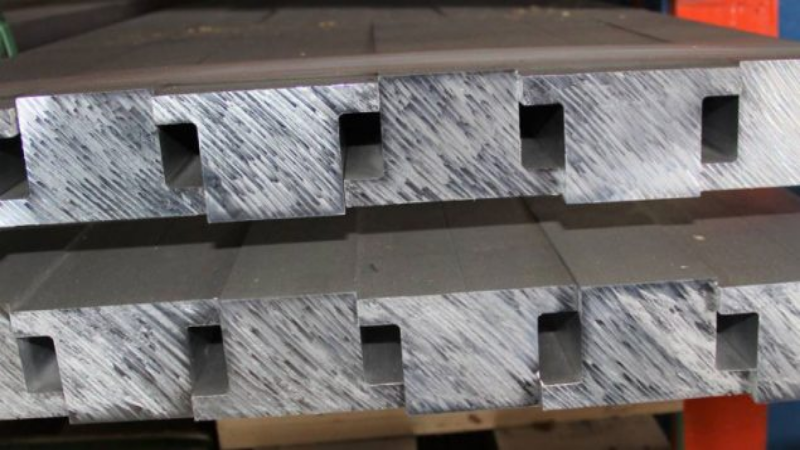

Various types of components can be created through the extrusion process through the transformation of aluminum alloy. As aluminum alloy is heated it is also softened and forced through a hydraulic press or ram and then through steel dies that develop the required shape, the shapes that result from extruding aluminum are developed as the billet passes through the die.

The Benefits of Aluminum Extrusion

In order to prevent corrosion, no unique treatment of the metals is required. In addition, as a result of the aluminum oxide being bonded to its service, which creates a defense against outside elements, aluminum has an inherent natural resistance to terror and wear.

When a building sways or moves, aluminum offers resistance against these forces as a result of its flexibility. In addition, this material can sustain impacts very efficiently and also keep its strength at the same time. Aluminum is a nonmagnetic material and can be used safely around magnetic fields and sensory magnetic devices.

An experienced and dependable aluminum distributor can provide extruded aluminum shapes based on your exact project specifications. In addition, a supplier that provides precision sawing can ensure that your aluminum parts and shapes are created and used in your application or project and processes with the necessary precision.